The Hidden Side of Exocad: 6 Ways to Maximize Its Power

Exocad is undoubtedly one of the most powerful design software tools out there.

Digital dentistry is becoming increasingly widespread with the advancement of technology. One of the most prominent software solutions in this transformation is Exocad. Developed for dental professionals and laboratories, this powerful CAD software stands out with its precision, speed, and flexibility. So, what exactly is Exocad, and why is it preferred in the field of digital dentistry?

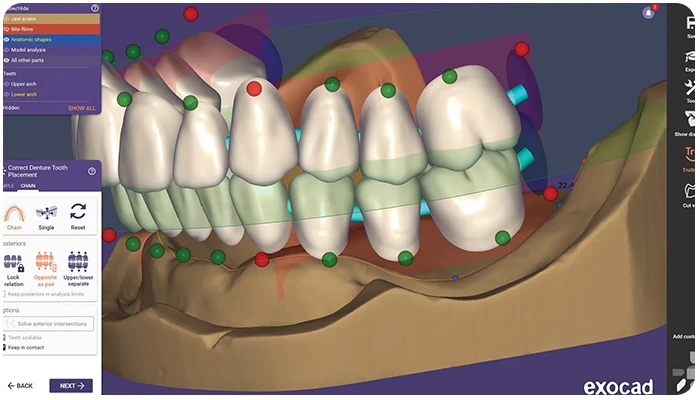

Exocad is a computer-aided design (CAD) software developed specifically for the digital design of dental restorations. Thanks to its user-friendly interface, extensive module options, and high processing capacity, it is widely used in both clinical and laboratory settings. Exocad holds a distinctive place among dental CAD software due to its modular structure, which allows users to customize the software based on their needs (Zimmermann et al., 2015).

One of Exocad’s key features is its modular system. Users can add only the modules they need in addition to the core software, allowing for a personalized and cost-efficient setup (Revilla-León & Özcan, 2019).

Thanks to its powerful algorithms, Exocad processes data faster than many other CAD systems. This speed enables the completion of large-scale restoration projects in a shorter time and optimizes production workflows (Patel et al., 2020).

Exocad is compatible with a wide range of intraoral scanners, milling machines, and 3D printers. This flexibility allows seamless integration with existing hardware infrastructures (Ahlholm et al., 2018).

The software enables highly detailed and anatomically accurate restorations that look natural and function optimally, increasing clinical success and patient satisfaction (Zitzmann et al., 2007).

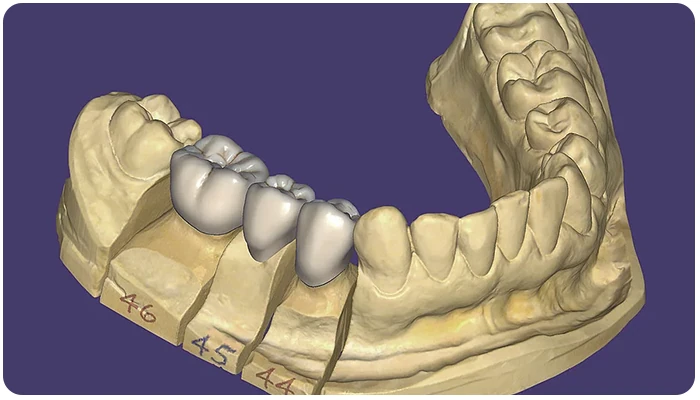

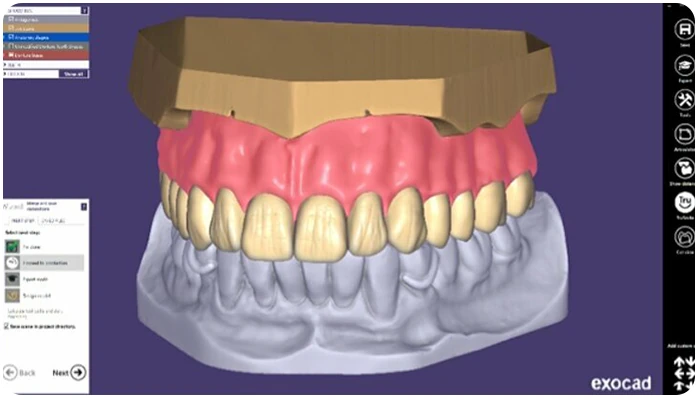

Used for basic restorations such as crowns, bridges, inlays, onlays, and full dentures. Scanned data is imported and restorations are digitally designed.

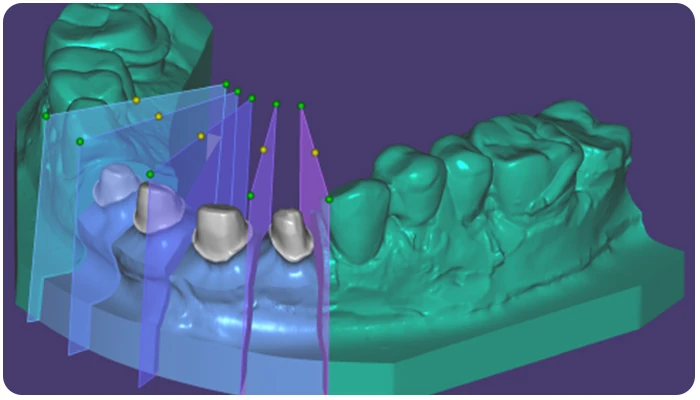

Enables the design of implant-supported restorations, including optimization of angulations and screw channels (Papaspyridakos et al., 2014).

Supports aesthetic planning by allowing digital smile designs based on facial images of the patient.

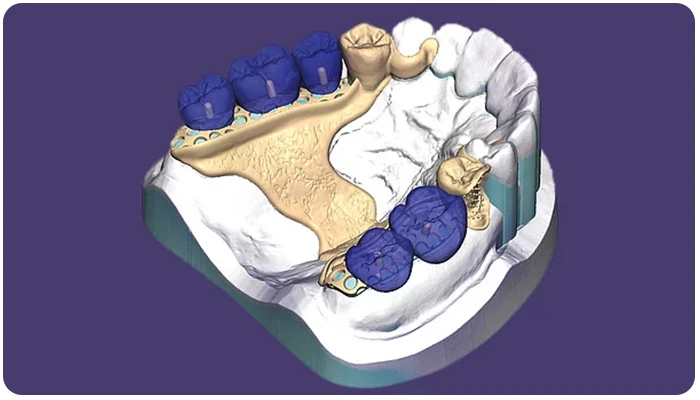

Used for the design of partial denture frameworks, making it ideal for CAD/CAM-based removable prosthodontics.

Generates printable STL files from scan data, allowing the production of physical models via 3D printing.

Used for the digital design of complete dentures, offering more precision and faster turnaround than traditional methods (Goodacre et al., 2012).

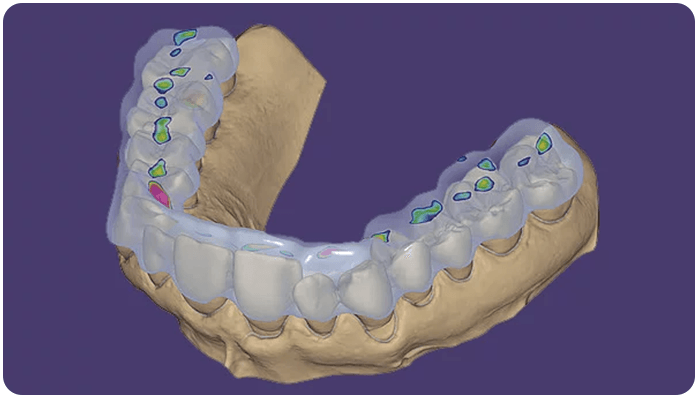

Dental Laboratories: Used to create restorations like crowns, bridges, implant-supported prostheses, and clear aligners. Dentists: Enables digital smile design, implant planning, and provisional restorations. Orthodontists: Useful for clear aligner production and orthodontic treatment planning.3D Printing Users: Easily exports STL files compatible with dental 3D printers for model and guide fabrication.

The evolution of digital dentistry has made treatment processes more predictable, faster, and patient-centered. Exocad stands at the core of this transformation by offering users efficiency, flexibility, and accuracy. With its modular structure, broad compatibility, and intuitive design, it provides a powerful solution for both clinical and laboratory applications. Today, clinics that fail to adopt digital systems fall behind in competitiveness, while those that work with software like Exocad take a significant step forward.